-

Email

-

Phone

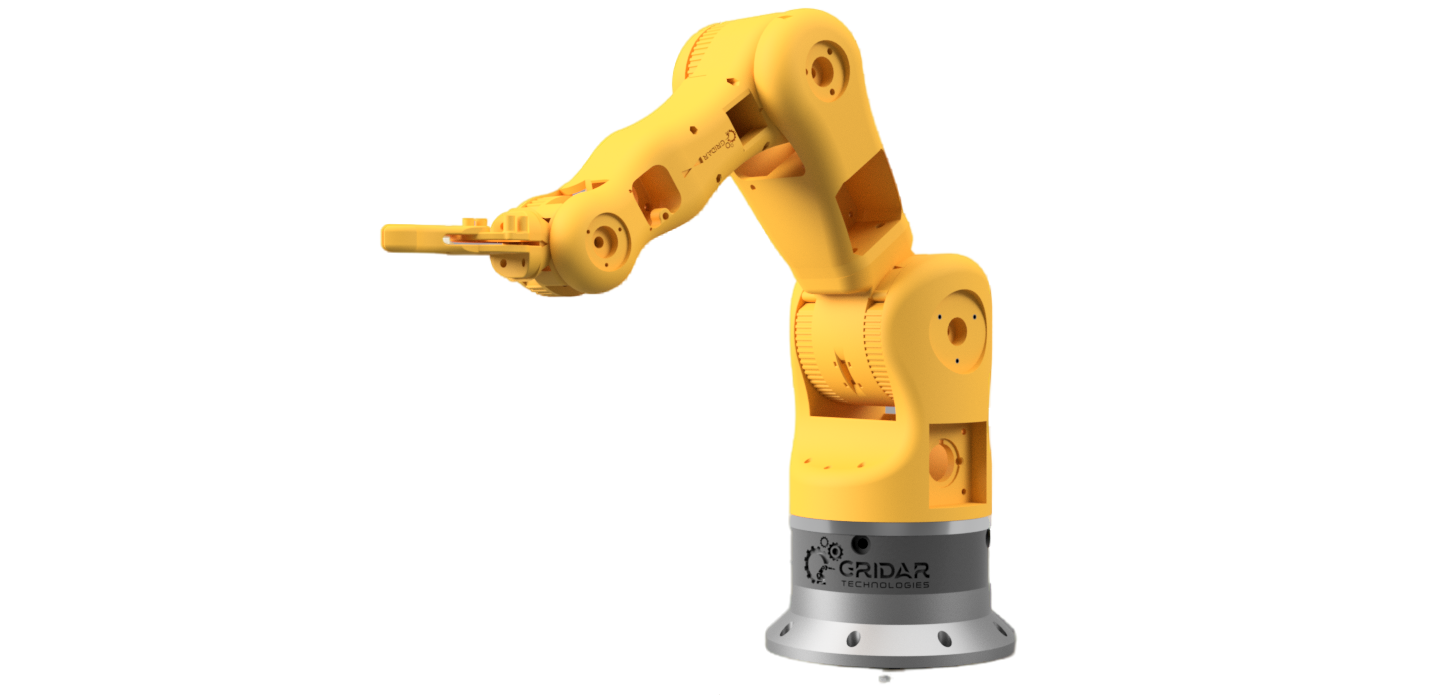

GT ROBOT – Five/Six-Axis Articulated Robot

GT ROBOT is a five/six-axis articulated robotic arm designed for learning, training, and industrial application development. The structural components of the robotic arm are 3D printed using Gridar Technologies MATRIX Pro / GT-300 3D printing systems, ensuring precision, strength, and repeatability.

The robot is easy to program and operate. Its controller software supports robot programming, 3D simulation, integration with input/output systems, and vision system compatibility. GT ROBOT is a plug-and-play solution, enabling quick setup and deployment.

It provides hands-on experience in industrial applications such as pick-and-place, assembly, and palletizing, making it ideal for learning and training applications.

Made in India

Built for Tough Usage

Quality

Reliability

Technical Specifications

| Parameter | Specification |

|---|---|

| Robot Type | Articulated Robotic Arm |

| Number of Axes | 5 |

| Vertical Height | 600 mm (excluding end effector) |

| Working Reach | 100 mm – 450 mm |

| Rated Payload | 0.5 kg |

| Repeatability | ±1.0 mm |

| Axis 1 (Base Rotation) | 240° |

| Axis 2 (Shoulder) | 180° |

| Axis 3 (Elbow) | 180° |

| Axis 4 (Wrist Pitch) | 340° |

| Axis 5 (Wrist Rotation) | 180° |

| Actuation Type | Electric |

| Drive System | Stepper motors |

| End Effector | Servo-driven gripper |

| Controller | RAMPS 1.4 with Arduino Platform |

| Control Software | Quantum Robotic Arm Control Software |

| Input / Output Voltage | 12 V DC |

| Power Supply | 230 V AC, 50 Hz |

| Mounting Type | Table-mounted |

| Net Weight | 15 kg |

Software

Supports execution of up to twelve (12) axes within a single G-code file.

Note: While a standard six-axis robotic arm may be sufficient for basic tasks, additional auxiliary axes are utilized in real-world applications to extend reach, improve positioning, and assist in complex operations.

Joystick-based manual control for intuitive operation and teaching.

Servo-controlled gripper support.

Motor enable/disable functionality for safe operation and maintenance.

Automatic G-code recording during teaching or manual operation.

Ability to execute G-code line-by-line for debugging, validation, and instructional purposes.

Supports storage of unlimited G-code files, subject to controller memory.

Automatic return-to-home position functionality.

Mechanical

| Component | Description |

|---|---|

| Structural Parts | High-strength 3D-printed components for lightweight and modular construction |

| Bearings | Precision ball bearings for smooth and stable motion |

| Linear Guidance | Hardened smooth rods for accurate linear movement |

| Transmission System | Belt drive mechanism for efficient power transfer |

| Motors | High-torque stepper motors for precise positioning |

Machine

Applications

Educational Institutions

Robotics labs, engineering colleges, STEM programs

Light Automation

Basic pick-and-place and motion demonstrations

Research & Development

Prototyping, algorithm testing, motion studies

Skill Development & Training

Industrial robotics fundamentals and automation learning

.png)