-

Email

-

Phone

Welcome to

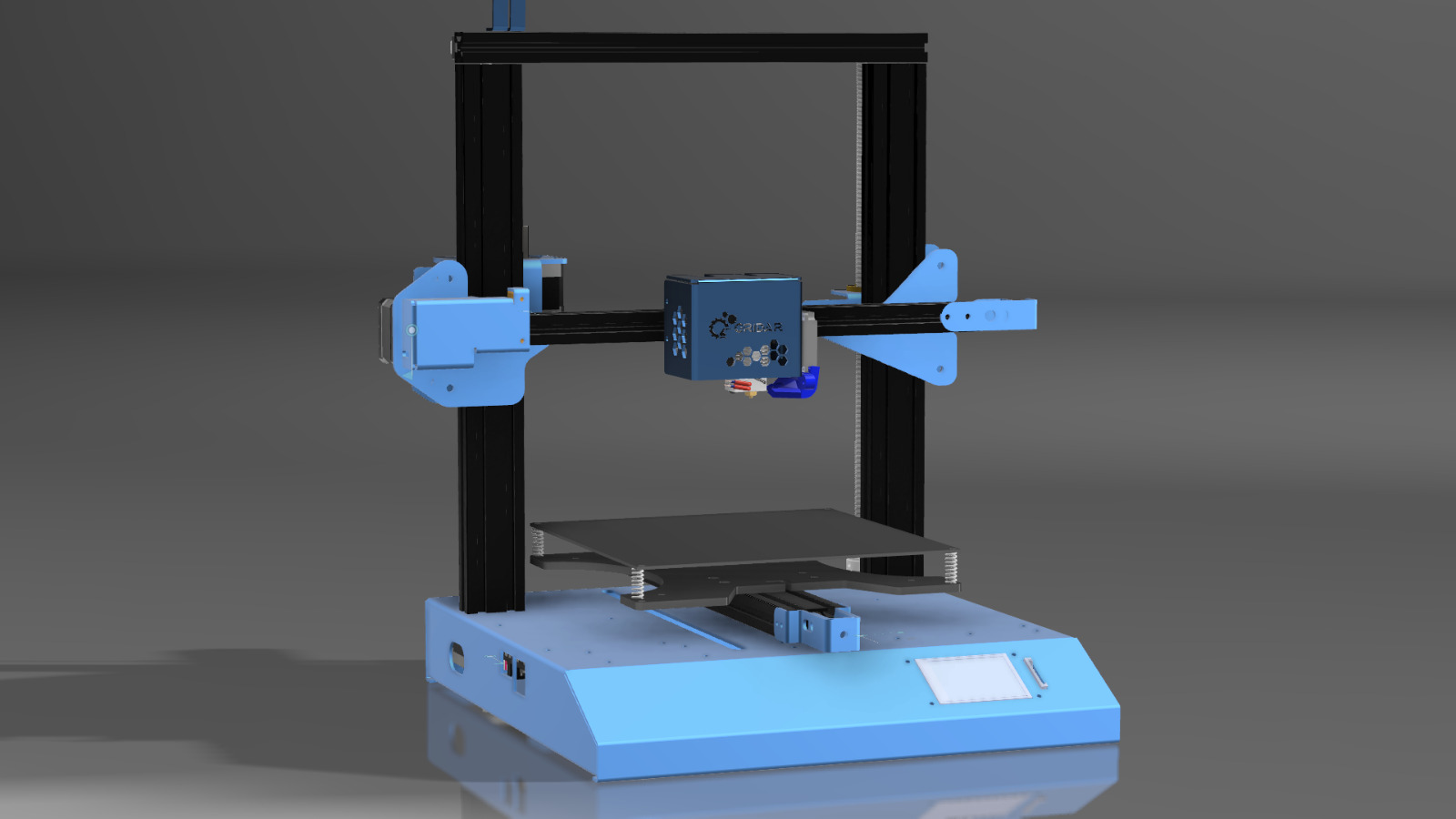

Gridar Technologies

Gridar Technologies is an Indian engineering solutions company specializing in the design and manufacture of industrial 3D printers, rapid prototyping machines, light automation systems, and robotics and collaborative robot (cobot) solutions. We serve manufacturers, R&D centers, educational institutions, and quality inspection teams with reliable, high-precision technologies.

Who We Are

Rapid Prototyping Machines

Gridar Technologies’ industrial-grade 3D printers are ruggedly built to help you move seamlessly from prototype to production. Designed for small businesses, tech labs, colleges, busy offices, makerspaces, print and prototyping shops, and manufacturing plants, our printers deliver fast, reliable, and affordable 3D printing with low noise and high precision.

Light Industrial Automation

We provide custom-made, industrial-grade linear drives for automation applications. Our solutions include XY tables tailored to customer requirements, as well as linear drives using ball-screw and belt-drive mechanisms to suit diverse industrial needs.

Robots for Learning Purposes

Using components tested and proven in our rapid prototyping machines, we design and build open-source 6-axis robots for educational and training purposes. These robots are offered at an affordable cost to educational institutions and training centers, enabling hands-on learning in robotics and automation.

6+

Years of Experience

9+

Industries Served

20+

Engineers

Schedule a meeting or book a demo

Contact UsQuality, Reliability & Trust

Quality

We engineer our 3D printers with a rigid sheet-metal chassis constructed using high-grade aluminum components to effectively suppress vibrations and deliver stable, accurate prints. An industrial-grade ball-screw or lead-screw driven Z-axis eliminates Z-wobble, ensuring smooth layer stacking and superior surface finish. Most sub-assemblies are precision CNC-machined to maintain tight tolerances, resulting in consistent, high-quality 3D prints you can rely on—from rapid prototyping to production-ready parts.

Support

Gridar Technologies provides comprehensive end-to-end customer support. All products are supplied with a one-year manufacturer warranty. Post-warranty, we offer Annual Maintenance Contracts (AMCs) to ensure continuous technical support, regular maintenance, and reliable operation of our machines with minimal downtime, supported by the fact that most components are designed and manufactured in-house.

Reliability

Developing reliable 3D printers and robot/cobot systems begins with robust engineering and systematic product development, supported by high-quality manufacturing processes. This includes careful selection of components, followed by extensive testing and validation to ensure consistent performance, safety, and long-term reliability.